Ductile cast iron is a versatile material that can be employed in numerous product applications, providing an affordable mechanical turnkey solution for many industries. Because products can be cast in one piece and use less material, spheroidal graphite castings are an affordable alternative to steel forgings, stampings, and fabrications. With a host of ductile cast iron properties — particularly yield strength, tensile strength, and elongation — it profiles beautifully in any situation where a rugged and dependable alloy is required.

Urick has produced a wide range of products and product components in our state-of-the-art ductile iron foundry. Here are a few examples of our quality ductile iron castings.

Internal parts for couplers on train cars

SG iron's ability to resist pulling and vibration forces makes it a natural choice for couplers connecting train cars on locomotives.

Shifter forks for transmissions

Ductile iron castings are widely used in the high-heat/high-friction environments of automotive/heavy truck transmission systems.

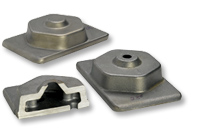

Fasteners with cast threads

Urick utilizes the finest grain sand in the industry for superior accuracy, ensuring fastener threads with the tightest, most secure fit.

Suspension Arms

With industry-best nodularity, Urick's ductile iron castings were made to handle the ups and downs and twists and turns of challenging terrain.

A pattern of excellence

Prototype worth preserving? We maintain lifetime patterns for our customers, allowing us to scale with client needs and shorten lead times. Whether we're starting anew from your engineering blueprints or picking up where we left off, we look forward to your partnership.